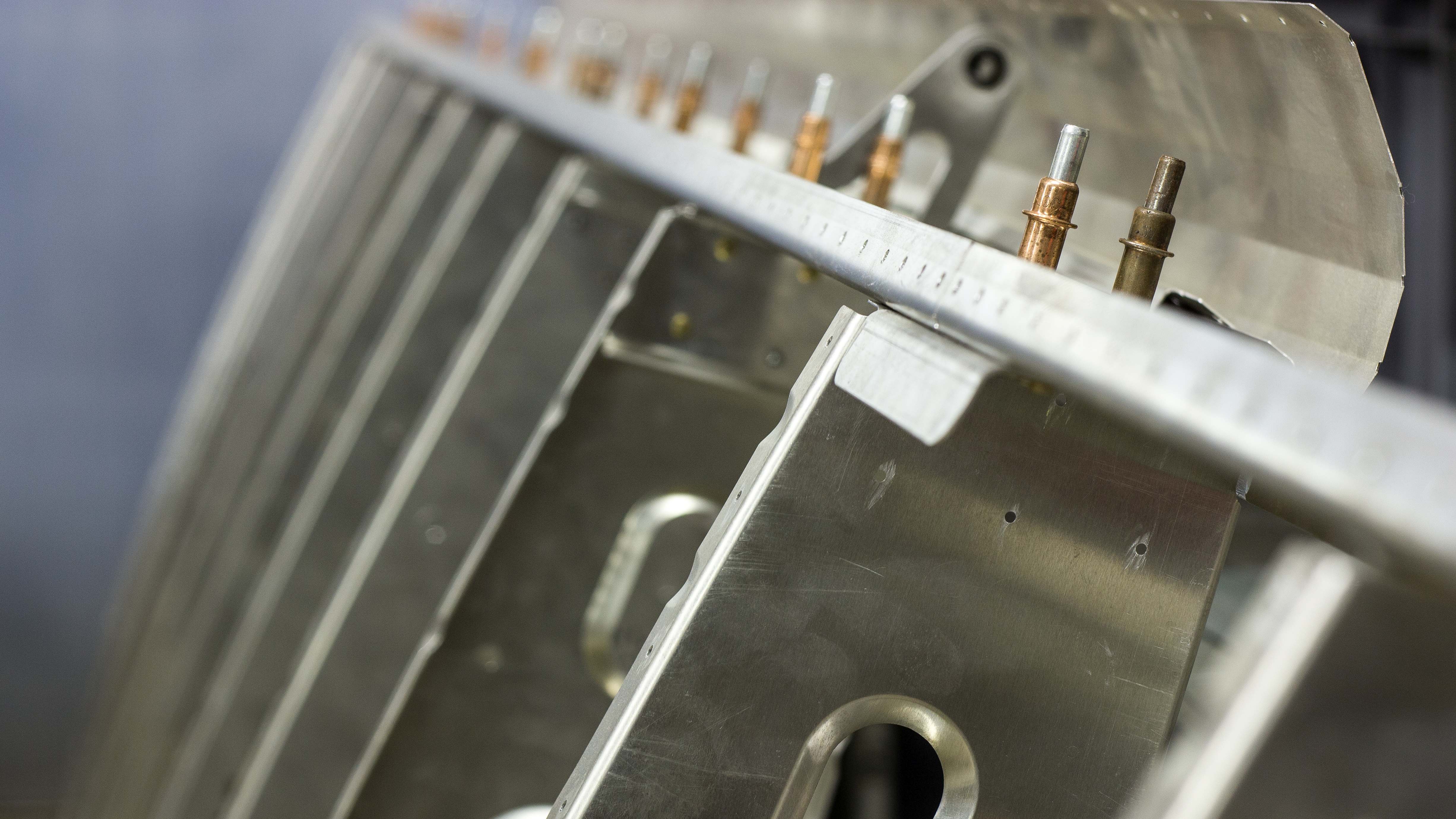

MATCH HOLE TECHNOLOGY

Match Hole technology is a very effective way of manufacturing and building metallic aircraft.

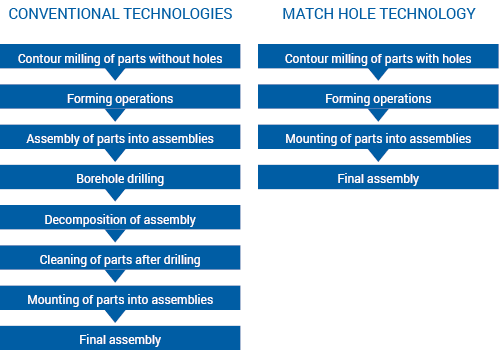

The principle lies in drilling holes for the connecting material already in the stage of metal cutting – milling process. The parts thus obtained are then passed on to other shaping operations – bending and forming. After the subsequent surface treatment, the parts are passed on to final assembly. The sophisticated Match Hole Technology system ensures that the individual parts fit together with a minimum of finishing operations. The building process is graphically shown on the diagram below.

The main advantage of this system lies in its effectiveness. Implementation of MHT drastically reduces production costs and times, eliminates the need to use complex tools/jigs to mount individual parts in assemblies and reduces the need for experienced personnel.

The advantages of this system will be appreciated especially by amateur builders, for whom the aircraft airframe assembly is very simple and comfortable.